Laser Cutting

High quality laser cutting up to 25mm Mild Steel, 20mm Stainless Steel and 20mm Aluminium. Fiber lasers are the most efficient way in laser cutting. The laser beam is created by an active fiber and transmitted over a transport fiber to the machine cutting head. Fiber lasers are significantly smaller than CO₂ lasers and generate several times the power from the same amount of current. With a fully automated tower system it also gives the ability to load 9 tonnes of metal which means more efficient use of laser times. The MPF pallet loader allows us to run throughout the day with minimum manpower and also lights out

On-Site Nitrogen Generation

We are impressed with the performance of the system and the organisation and professionalism of Atlas Copco at all stages from the initial trial to final commissioning. We are saving on the cost of nitrogen, saving on energy consumption, and now have more capacity and a variable system for future developments.

More Nitrogen at a Lower Cost

The delivery rate of 99.99% purity nitrogen generation from the unit was established as 19 Nm3/hr at 300 bar(g) to charge the onboard 16 bottle manifold cylinder pack (MCP) thereby producing 408 Nm3 over a 12-hour period. When running flat out, that equates to 57 MCPs a month, 30% more in comparison to the nearest competitive offering that was limited to a maximum output of 44 MCPs.

The nitrogen generator operates with Pressure Swing Adsorption (PSA). The system works by separating nitrogen and oxygen molecules within the compressed air stream feeding the unit. PSA does this by trapping the oxygen using adsorption techniques. Adsorption takes place when oxygen molecules attach to a carbon molecular sieve (CMS) allowing the smaller nitrogen molecules to pass through.

The NGP+ generator’s low-volume, high quality absorbent medium provides optimum capacity to produce the nitrogen. Whereas other competitive systems require six volumes of air to produce one volume of nitrogen, Atlas Copco’s generator design requires a ratio of only four parts of air to one part of nitrogen.

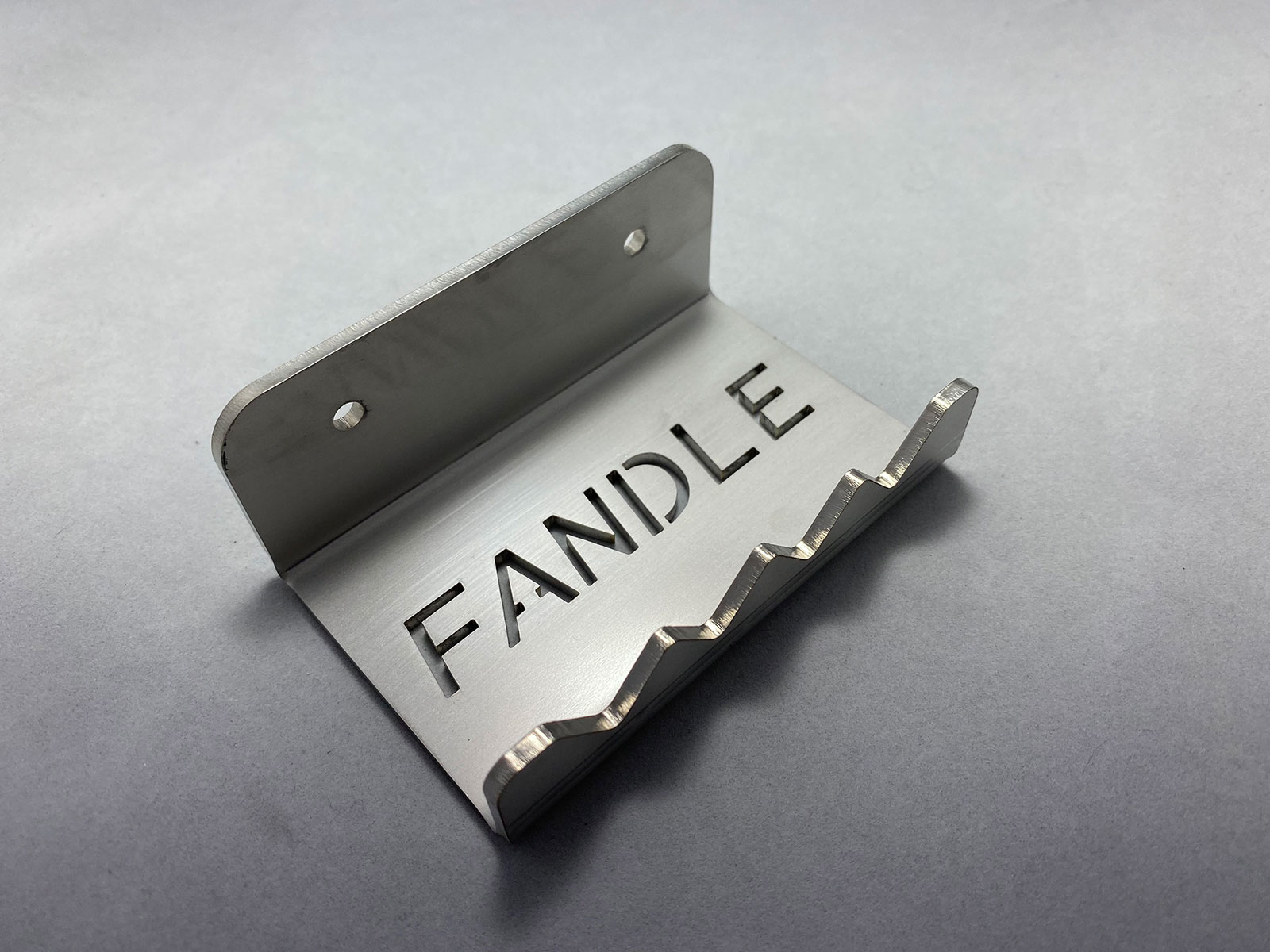

As an additional bonus the new facility enables ABi Laser to save on energy costs of other operations that can now utilise the unlimited on-site nitrogen supply. In addition to its mainstream metal cutting activity, the company employs lasers for tube cutting and engraving, as part of its other metal fabrication services such as folding, tapping and plasma.

Laser Cutting

High quality laser cutting up to 25mm Mild Steel, 20mm Stainless Steel and 20mm Aluminium.

Plasma Cutting

Plasma cutting maximum thickness: carbon steel 50 mm, stainless steel 50 mm.

Water Jet Cutting

Cold cutting process that cuts by using supersonic water to erode virtually any material.

Extra Services

End-to-end metal services provider: pressbrake, rolling, countersinking, tapping and more.