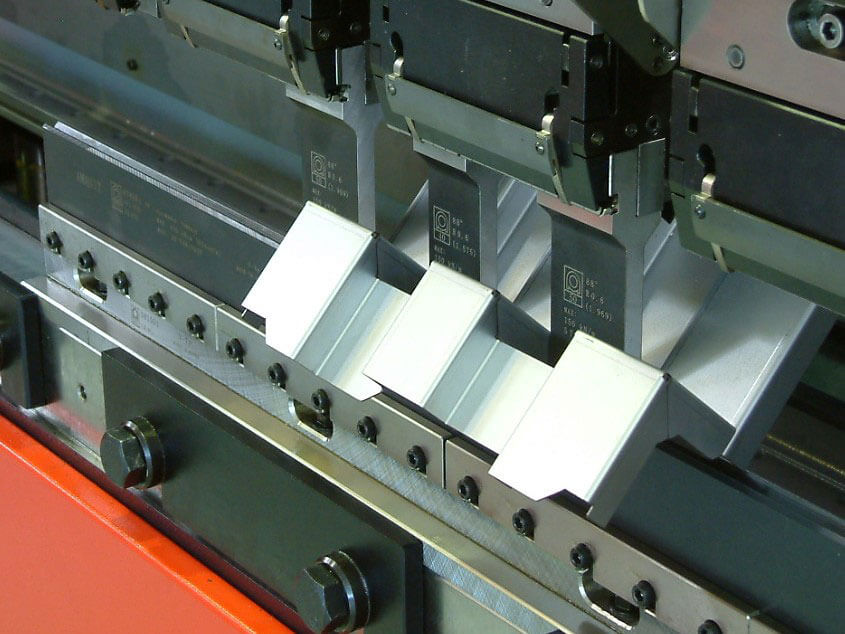

Pressbrake

The press brake is a machine pressing tool that is perfect for bending sheets and plate materials. It is most used for sheet metal. The forms predetermined bends that clamp the work pieces between the die and the matching punch. Because press braking has such adaptable capabilities, it has the potential to take on those forming operations that require profiles for parts that are smaller than average and may not be identical this also in turn Increases Efficiency and high-end precision and accuracy, of the bends needed to form the part.

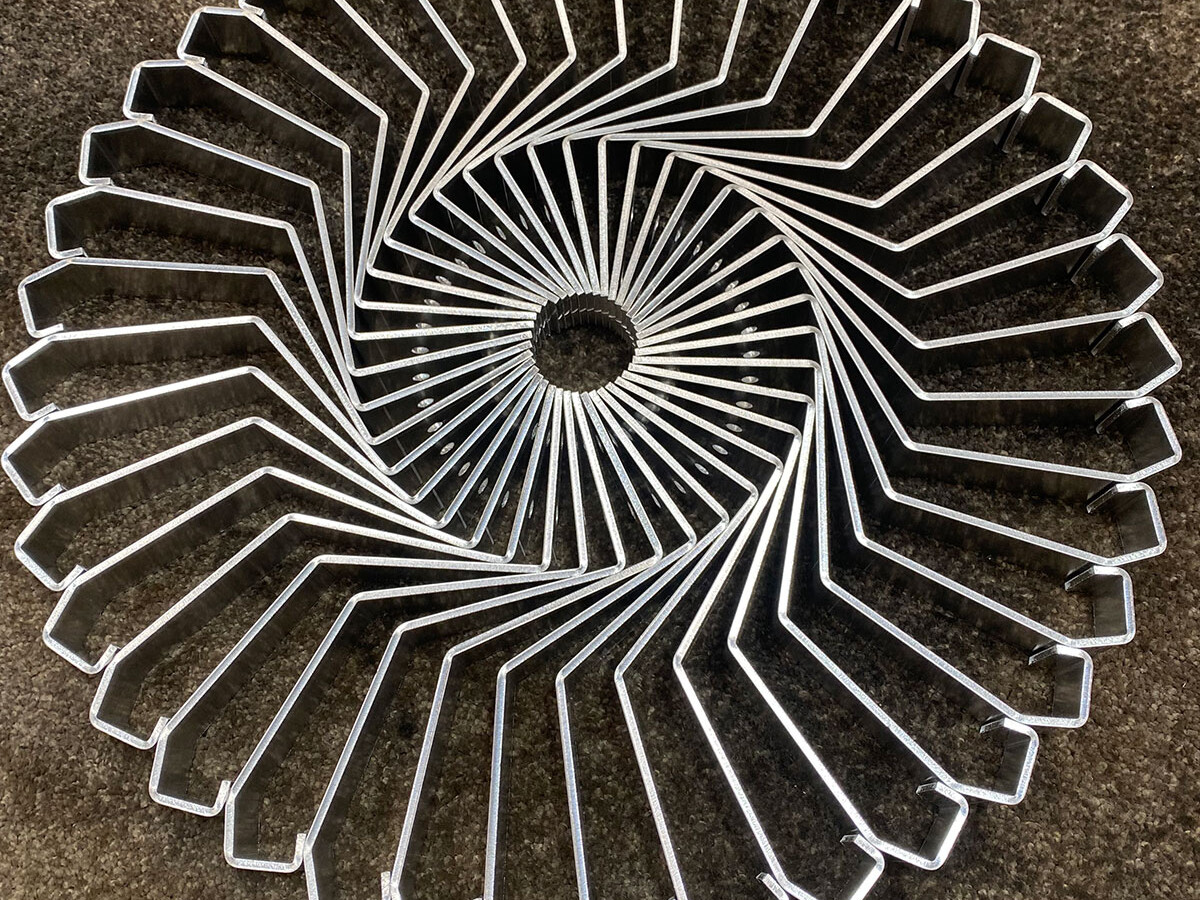

Rolling

Metal rollers are used to form rounded sections out of flat metal stock and sheet metal. Using rollers can form the shape of hoops, cylinders and cones or combinations of any of these forms.

Countersinking

Countersinking can be part of fabrication work that creates an conical hole to allow the insertion of a rivet, bolt, screw or any other fastening device. This is so that the fitted device will sit flush with the rest of the sheet metal, and the sink is made within an existing hole. Countersinking is a process for the post-processing of existing holes. This means that the countersink does not cut into the full material. There are different countersinks which fulfil different functions. Countersinking can widen the laser cut holes and facilitates subsequent tapping. When countersinking screws, space is created for the screw head so that it closes with the surface of the material.

Tapping

Tapping is a way to add threading to sheet metal, the tapping process creates a thread within the hole. with this process, Tapping in sheet metal is the use of a tapping tool to form material in a pre-cut or extruded thru hole, to create threads for engagement of a non-self-tapping screw. This application is typically needed for connecting one piece of sheet metal to another item.

Laser Cutting

High quality laser cutting up to 25mm Mild Steel, 20mm Stainless Steel and 20mm Aluminium.

Plasma Cutting

Plasma cutting maximum thickness: carbon steel 50 mm, stainless steel 50 mm.

Water Jet Cutting

Cold cutting process that cuts by using supersonic water to erode virtually any material.

Extra Services

End-to-end metal services provider: pressbrake, rolling, countersinking, tapping and more.